How to Select an Evaporator for a Commercial Cold Room

Introduction

In the world of refrigeration, cold room design is often centered around ensuring maximum reliability, especially in critical environments where downtime can lead to costly product losses. A common solution is to design cold rooms with 100% redundancy, where each key component—like evaporators—can independently handle the entire load. But what does that actually look like in practice, and how do different configurations affect system performance? Let’s dive into it.

Example 1: Two Evaporators with 100% Load Coverage

Let’s take, for example, a cold room with two evaporators, each capable of handling 100% of the cold room load. These evaporators are operated by separate systems. This design offers peace of mind because if one unit fails, the other can seamlessly take over without any issues, ensuring continuous cooling. In this setup, the two evaporators can be installed facing each other without worrying about airflow interference, as they run in rotation. For instance, one could run during the day, while the other runs at night. The night unit can even be installed near the door without any concerns about sucking in hot air that could lead to icing. This design offers flexibility, ease of maintenance, and reduces wear and tear by splitting the operational time between the two units.

Example 2: Two Evaporators with 50% Load Coverage

Now, let’s consider a more cost-effective approach: two evaporators, each handling 50% of the cold room load. This design can still achieve redundancy but requires a more sophisticated operating logic to ensure smooth performance. Without proper management, this design can be tricky to run.

Synchronized Defrost Cycles

Both evaporators must start and end their defrost cycles simultaneously to maintain defrost efficacy. If one evaporator is cooling while the other is defrosting, you risk inefficient defrosting.Simultaneous Run and Cut-Off

Both evaporators need to start and stop at the same time. If they are controlled individually, each evaporator could receive its own temperature data, leading to inefficient cooling cycles.Potential Issues in a 50% Load Design

If one evaporator reaches the desired temperature and cuts off from the cooling cycle, you are left with only 50% of the system handling the cold room load.

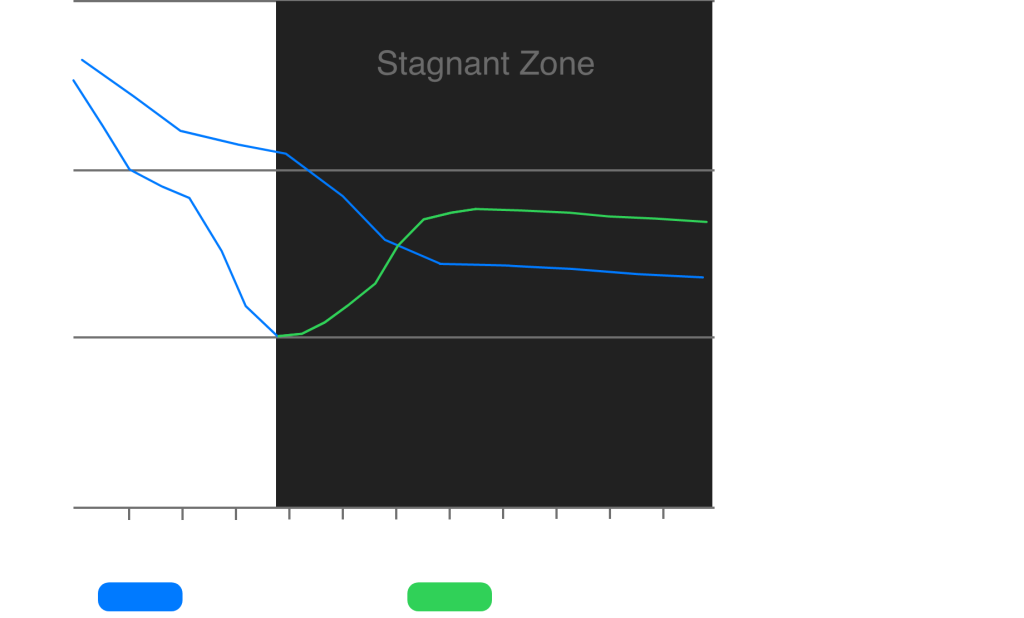

Scenario 1: Regulating Band Issue (Stagnant Zone)

In this case, the remaining evaporator might be able to maintain the temperature but may not reach the desired setpoint, causing the system to get stuck in the regulating band. For example, if the desired room temperature is -18°C and the hysteresis is 3°C, the evaporator would cut off at -18°C and kick back in at -15°C. If the remaining evaporator cannot pull the room temperature below -18°C, both evaporators will get stuck: one waiting indefinitely to kick in and the other waiting indefinitely to cut off.Scenario 1: Scenario 2: Happily Ever After

In a more fortunate scenario, the remaining evaporator is able to pull down the room temperature, and both evaporators reach the desired temperature. However, this outcome is unlikely without proper coordination between the units.How to Overcome These Issues

One way to overcome this issue is by using a single temperature controller to manage both evaporators. In some cases, I’ve seen systems where the two evaporators are controlled by one temperature controller, which only takes readings from one evaporator’s coil temperature for defrost and the room temperature for regulation. This setup ensures that both evaporators run and defrost simultaneously, but it’s not optimal for defrosting. You cannot fully ensure that the evaporator not being measured has undergone a thorough defrost.

Scenario 1: Central Manager for Controllers

The best practice is to have a central manager to coordinate the two temperature controllers. One of the controllers would act as the master, and if one of the controllers finishes defrosting, it won’t immediately kick in for cooling. Instead, it will wait for the other to finish defrosting, and then both will resume cooling simultaneously. The same logic applies to temperature regulation: when one controller reaches the desired temperature, it won’t cut off until the other has also reached the setpoint.Scenario 1: Scenario 2: Happily Ever After

In a more fortunate scenario, the remaining evaporator is able to pull down the room temperature, and both evaporators reach the desired temperature. However, this outcome is unlikely without proper coordination between the units.Conclusion

Designing a cold room with 100% redundancy using dual evaporators offers clear advantages in terms of reliability and system security. Whether each evaporator is designed to handle 100% of the load or only 50%, it’s essential to consider the operating logic, defrost cycles, and control systems to ensure smooth, efficient performance. Proper management of these elements ensures that your cold room maintains its desired temperature without risking downtime or product loss.