How to Select a Thermostatic Expansion Valve: Understanding the Impact of Liquid Temperature

Introduction

Selecting the right thermostatic expansion valve (TXV) is a crucial step in designing a refrigeration system. After choosing the evaporator and compressor, the expansion valve is sized based on key parameters, including the evaporating temperature of the selected evaporator and the condensing, discharge, and liquid temperatures of the compressor. While some in the industry might take liquid temperature for granted, it’s a critical factor that must not be overlooked.

Case Study: Sizing an Expansion Valve for Two Compressors

Let’s examine the selection of a thermostatic expansion valve for two compressors with similar cooling capacities.

Operating Conditions

Evaporator Load

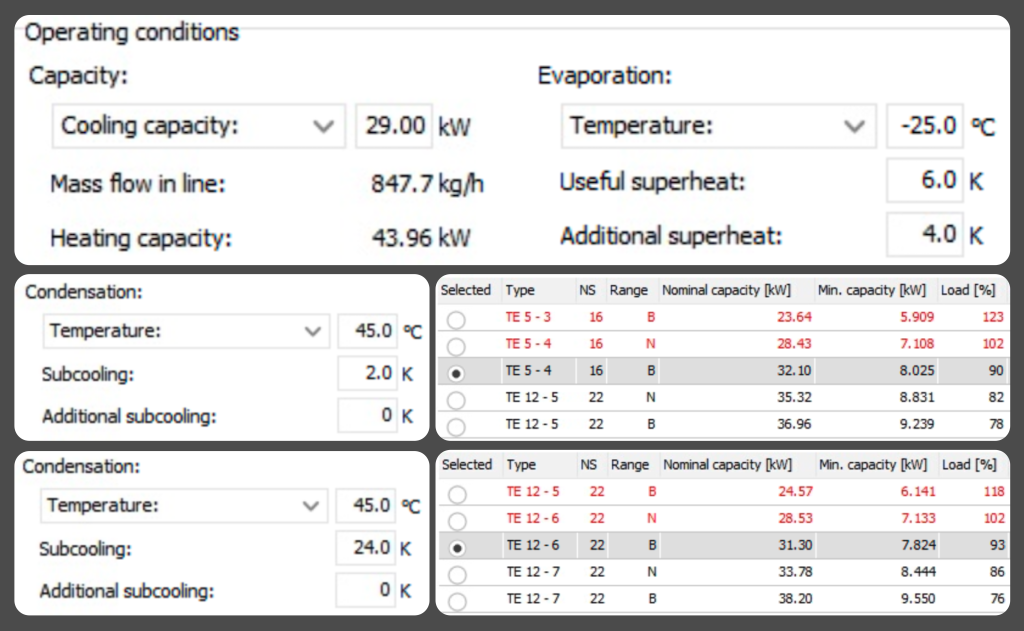

29 kWRefrigerant

R-507Evaporating Temperature

-25°CCondensing Temperature

45°CUseful Superheat

6KNon-Useful Superheat

4KSelected Compressors

Compressor 1: Bitzer 6GE-34y (Single-Stage)

Cooling Capacity: 29.2 kWCompressor 2: Bitzer S6H-20.2y (Two-Stage)

Cooling Capacity: 28.8 kWFin spacing impacts air circulation and defrosting performance. A lower FPI (wider spacing) is preferred in freezers to prevent icing, while a higher FPI (narrower spacing) is more suited for chillers where fast heat exchange is needed.

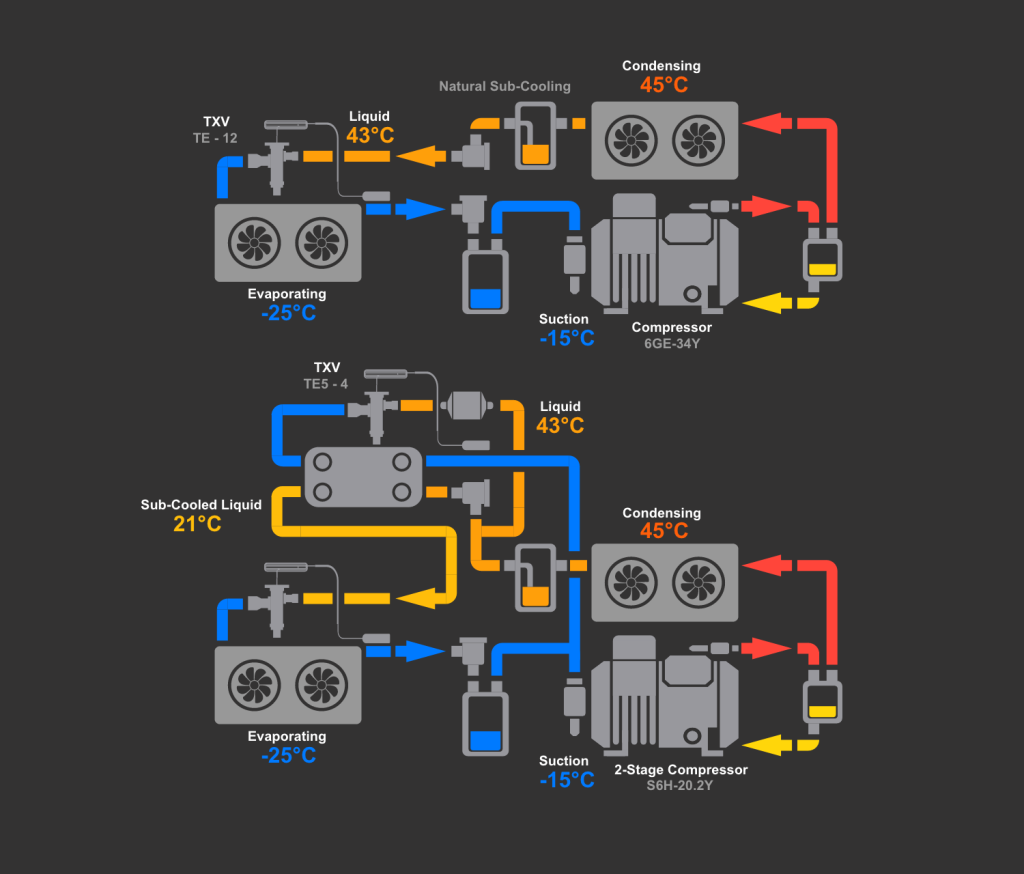

Step 1: Sizing for the Single-Stage Compressor (6GE-34y)

Using the given operating conditions (evaporating temperature, condensing temperature, superheat values, and cooling capacity), we input the data into Danfoss CoolSelector. The software suggests the TE 12 – 5 expansion valve model, which is the closest match to the evaporator load.

Step 2: The Challenge with the Two-Stage Compressor (S6H-20.2y)

When using the same operating conditions for the two-stage compressor, you might assume that the same valve (TE 12 – 5) would be appropriate. But here’s where things get tricky: the two-stage compressor has a sub-cooler, which brings the liquid temperature down significantly. While we often assume a natural sub-cooling of 1-2K (resulting in a liquid temperature around 43°C), the sub-cooler in this compressor reduces the liquid temperature as low as 21°C, creating a sub-cooling of 24K. This huge difference in liquid temperature drastically changes the requirements for the expansion valve.

Step 3: Adjusting for Liquid Temperature

When we adjust the liquid temperature to 21°C in the Danfoss CoolSelector software, the recommended expansion valve changes dramatically. Instead of the TE 12 – 5 valve, we now need a TE 5 – 4 model, which is much smaller in size.

Why the Difference?

If the larger TE 12 – 5 valve were used on the two-stage compressor (S6H-20.2y), the expansion valve would overfeed refrigerant into the evaporator. This overfeeding would result in liquid flooding back to the compressor, which could cause damage and reduce system efficiency.

Key Takeaway

When selecting a thermostatic expansion valve, it’s critical to account for the liquid temperature and sub-cooling in your system. In this case, a two-stage compressor with significant sub-cooling requires a much smaller expansion valve than a single-stage compressor with similar cooling capacity. Overlooking this detail can lead to system inefficiencies or even mechanical failures.